- 2024

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- 2010

-

-

-

-

-

-

-

-

-

-

-

-

- 2000

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- 1990

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- 1980

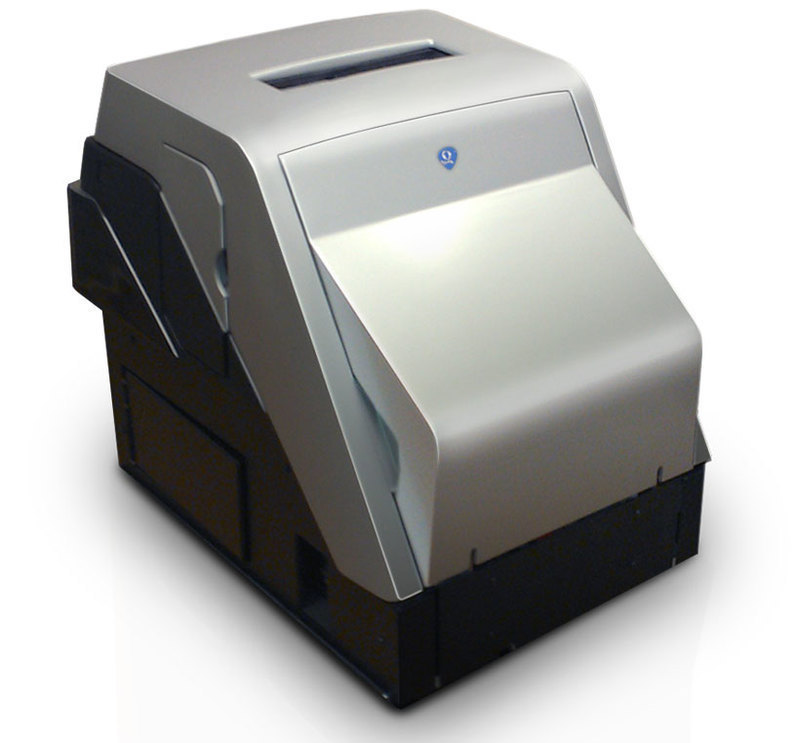

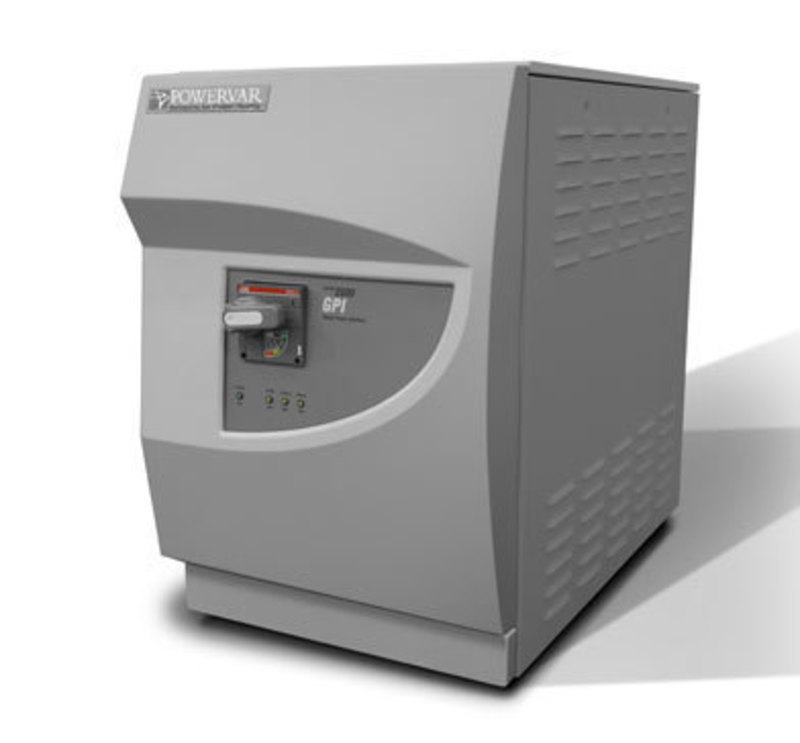

Bally Technologies

Lottery Terminal

Design Team: Cesaroni Design & Bally Technologies

Bally Technologies worked with Cesaroni Design to develop a new product utilizing structural foam. Working closely with Bally, we executed the structural foam project from sketches, renderings, assembly details, piece part drawings and prototypes.

After analyzing manufacturing processes, a structural foam product emerged as the only logical choice. The use of structural foam assisted in making a product superior in appearance as well as in strength and durability.

Concept renderings were generated to determine the aesthetics. A foam core mockup was then created to quickly test basic ergonomics. A wooden styling model came next, followed by a functional prototype. As each of the 3D form factors was created, more accurate detail drawings were completed.

The structural foam made it possible to keep the size to a minimum. This was partially the result of fewer ribs and support walls needed, which increased internal space for components. The structural foam allowed a minimum of exterior draft on two tall walls. This was a key factor in the overall appearance. To bring the finish of the parts closer to perfection, a smooth fog coat of paint was applied.

Project deadlines were met by keeping lines of communication open between the client, designers, molder and toolmaker.

Bally Technologies

Lottery Terminal

Design Team: Cesaroni Design & Bally Technologies

Bally Technologies worked with Cesaroni Design to develop a new product utilizing structural foam. Working closely with Bally, we executed the structural foam project from sketches, renderings, assembly details, piece part drawings and prototypes.

After analyzing manufacturing processes, a structural foam product emerged as the only logical choice. The use of structural foam assisted in making a product superior in appearance as well as in strength and durability.

Concept renderings were generated to determine the aesthetics. A foam core mockup was then created to quickly test basic ergonomics. A wooden styling model came next, followed by a functional prototype. As each of the 3D form factors was created, more accurate detail drawings were completed.

The structural foam made it possible to keep the size to a minimum. This was partially the result of fewer ribs and support walls needed, which increased internal space for components. The structural foam allowed a minimum of exterior draft on two tall walls. This was a key factor in the overall appearance. To bring the finish of the parts closer to perfection, a smooth fog coat of paint was applied.

Project deadlines were met by keeping lines of communication open between the client, designers, molder and toolmaker.